My first attempt at pressing a DIY linoleic oil was with Black Oil Sunflower bird seed that I was able to purchase cheaply at $19.00 per 40 pound sack. As I wrote above, this may be a person's best logical gamble in trying to purchase a high linoleic acid oil when considering that Agribusiness' goal seems to be producing a seed of various types with very low linoleic levels in favor of Oleic Acid content--if price is a concern. So far, the bird seed industry seems to have no interest in whether their purchased seed for resell is high linoleic or Oleic types. They will use what ever they can buy cheaply.

My Chinese press had some difficulty pressing oil from the sunflower black oil seeds. Some times, it seemed to clog up, laboring intensely. I am not sure why? Probably the high hull content along with various debris found in the seed contributed. Maybe my electric motor was not heavy duty enough for the bigger, thicker hulled black oil types? The black oil sunflower seeds often came with a lot of debris in the sacks consisting of twigs and other artifacts which I tried to pick out before pouring into the press hopper. That is some what of a hassle and you will never get them all! I think I need a heavier duty press, if I plan to press Black oil sunflower seeds much in the future. Maybe one with at least a 1000w motor?

My second seed attempt was a generic safflower bird seed which I purchased at the local feed store for US$24.00 for 50 pounds. It seemed to produce a much cleaner oil than the Black oil sunflower seeds. As far as cleanliness of the seed, there was still a few thin stems mixed in with the safflower seed, but it seemed much cleaner than the Sunflower seeds. My Chinese press seemed to have an easier time at producing oil from safflower than Sunflower. From my first attempt, I pressed 400 ml of oil from a 3 lb volume of safflower seed. My second attempt using my Chinese press was with 5 pounds of safflower seed. I had some trouble this time with the seed meal clogging the end resulting in labored motor performance and reduced oil output. I suspect it was because of the small hard twigs in the seed that bogged down the screw. I carefully picked out those twigs in later fed batches and the press worked much smoother, better, faster. On my 2nd attempt at pressing 5 pounds of safflower, I collected around 750 ml of oil. It produced a much cleaner oil than the black oil sunflower seed, but not quite as clean as flax seeds. I plan to purchase some Nutrasaff variety safflower in the near future that will guarantee me a high linoleic acid percentage in that oil plus has 40% less hull to clog up the screw.

I just received my first order of Nutrasaff in a 50 pound bag (packaged by Safflower Technologies, Int., Fairview, Mt (406-742-5401) through the Des Moines Feed Company. It seems a very clean seed and my cheap Chinese seed press had little problems producing oil from it. From 3 pounds, I produced 475 ml of oil which I compare to a previous 3 pounds of regular safflower seed which produced 400ml. So, it does seem to contain more oil as advertised! Nutrasaff will be my prime high Linoleic oil in the future and should be a good seed for those with the cheaper seed presses.

In the end, I have come to the conclusion that I need a heavier duty seed press if I plan to press larger amounts of oil for friends and family. These cheap Chinese models have fixed motor speeds, fixed distance from the screw to the end crush plate, and fixed tip size through which the meal is expelled. All of these factors really need to be adjustable for each type of seed and seed moisture content. Each of these adjustments will have an effect on each other and the final oil product. Proper record keeping is necessary. A Chinese press limits these adjustments to only one variable which I deem inadequate. The adjustments needed to be found in the ideal seed press:

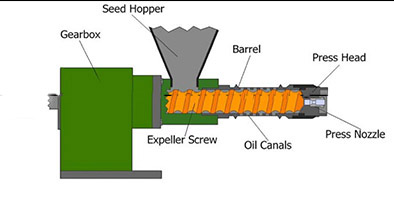

1) Distance between screw end and Crush Plate. . . . . . . . As the space is made smaller between the screw end and crush plate, the press's force increases creating greater pressures. Too large of a distance and the meal will pass through the end with less oil extracted. The key is to have just the right amount of space adjusted to allow the meal to pass through the end nozzle while extracting the maximum content of the seed oil. Many presses will have this adjustment made by turning its head's threads in or out. As small as a 1/16 of a turn can make a large difference! Measuring thread distances should be recorded for future use and as an indication of crush plate placement.

2) Motor Speed . . . . . . . . . . . . . . . . . . . Your more expensive, sophisticated presses will have a variable speed drive. A faster turning screw will force the seed through the screw faster allowing less time at the crush plate, but one has to balance the speed in combination with nozzle size to determine oil output. It is commonly known that a higher speed can cause a decrease in oil production. To a point, the slower the seed press motor turns, the more oil production is achieved. Many will say that the higher screw speeds will also rise temperatures, but I find that dubious. My view, depending on the nozzle tip diameter used in combination is that it can actually lower temperatures at the crush plate as the seed is forced through the nozzle faster with less friction. Thus, the less time at the crush plate will generate less heat with the oil production dropping! A 2011 journal article had this to say: "The effect of difference speeds to the percentage of oil yield is related with the duration of pressing process. Slow speed would probably extend the pressing process and result to the increase of heating process in the machine (Evangelista, 2009). This condition might result to the oil yield to flow easily and also increased (Lutanda ltd, 1988)."

3) Nozzle Tip Diameters. . . . . . . . . . . . . many presses have multiple tips with varying diameters that can be wrenched on the end to affect the back-pressures of the flowing seed meal. Tips can vary from 5mm to 15mm depending on seed type and moisture content. Larger tip sizes will allow the seed meal to pass through faster with less pressure. This will often hurt oil extraction volumes negatively. Too small of a tip diameter will stop the flow of seed meal all together. It is all a delicate dance. Some suggestions for tip diameter settings: rape seed- 5,6,7mm, flax seed- 7mm, Sunflower seeds with hull- 10mm, and Sunflower seeds hulless- 5 or 7mm. The same before mentioned 2011 journal article had this to say: "The size of the nozzle also related with the pressing process. Smaller size of nozzle might add pressure to the seed which thus promote heat to be produced by the result of the collision between the shaft screw and the seeds and also between the seeds themselves."

------------------------

My cheap $300 Chinese press worked very well for me for years when I only did whole flax seed where I only had to supply my own personal needs, but when I started extolling the virtues of the Budwig oil/protein supplement to family and friends, it suddenly created a need for larger and faster amounts of oil. Plus, with my discovery of how important a high linoleic seed oil was and which needed to be incorporated into the Budwig formula, I needed to up-grade!

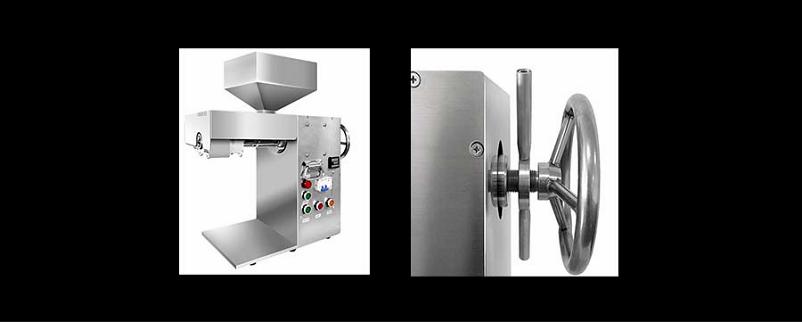

I looked over what the Chinese had to offer which wasn't much in their less expensive models. They were all built pretty closely to the same design type with a stainless steel box housing for the electric motor and a small steel screw and barrel bolted on. They all had fixed motor speeds and fixed nozzle diameters. About the only thing I would be gaining by up-grading to one of these is a more powerful motor in the 1500w range. I did find one Chinese model pictured below that seemed to also have an addition of an adjustment wheel on one end that presumably allowed the operator to adjust space between crush plate and screw-end. That would be nice. Prices for this larger unit seemed to range between US$1200 to over $2000, plus add onto this shipping costs once it arrived at a USA port to my destination along with tariffs, and we were probably talking about a final cost close to $3000 or more! My only seeming alternative was the USA or European presses that started at around $6000 and up.

Dr. Johanna Budwig wrote a number of books in German with only a few being translated and published in English. Her 1977 work, above, Der Tod des Tumors (Death of the Tumors) has not been published in English. After corresponding with a Professor friend, Dr. Ilona Klein of BYU, I was stimulated into attempting a machine translation of that text. I have found translation software to be much better in recent years than in the past and I was pleasantly surprised that my attempts seemed rewarding and to some extent surprising when compared to her English translations that are popularly out there now.

Der Tod des Tumors is written in two volumes. The first volume is rather dry and seemed to concentrate on the patenting process of her methods and financial concerns. The second part of this text is entitled Volume II, THE DOCUMENTATION and is much more interesting. It begins with a number of letters from her patients, some with very dire prognoses that are quite impressive of how her oil/protein diet effected cures for them. She does not list any failures and surely there were. Nevertheless, reading through them has to support her success rates as impressive to say the least.

I was primarily interested if this book would explain her choice of picking Flax oil as the best oil for treatment as all of her English translations seem to proclaim. I found that she was quite aware that other seed oils were beneficial. In Volume 1, page 86, she describes her patent invention as such: "The inventions contained in this notice of recognition include dipolar systems: On the one hand, highly unsaturated fats rich in electrons and fatty acids, as electron donors, as sources of the negatively charged Electrons made up of the quanta of solar energy, associated with the magnetic fields of the photons of the sun. These include e.g: Linseed oil, sunflower oil, poppy seed oil, soya oil, maize oil, maize germ oil, Wheat germ oil, rice oil, safflower oil, avocado oil and others. . ."

Thus, we see that she appreciates the value of a number of seed oils as possible treatment options from her patent description, even if she seemed to choose Flax oil (linseed oil) as her favorite oil of prescription. In Volume 2, a very interesting letter to Dr. Budwig from one of her patients, a Mrs. H.W. opens up a whole new vista in her prescribing of oils! Volume 2, page 114-115:

Mrs. H.W. writes: "In the summer of 1957, I had on my right breast, a small knot with leakage of liquid. In the autumn of 1957, I went to see a doctor who treated me with injections. However, there was no improvement. On the contrary, the knot became bigger and bigger and in consequence, an open wound. In the summer of 1958, the knot was already so large, I had increasing pain. I also lost weight and experienced languor. The liquid flowing out of the wart resulted in a strong crust formation. Because of this serious condition, I went looking for a doctor, who wanted to immediately admit me to the Cantonal hospital for surgery. Neither my husband, nor I could decide." Now the patient describes in detail what she did next. She also visited biological clinics. "But there was no cure, it continued to flow. In June 1959, I became a patient with Dr. Budwig and discussed with her about my case. She advised me to immediately switch to the oil-protein diet in especially linseed (flax) oil, sunflower oil, both cold-pressed in quark. In a month of this cure diet and oil/protein supplement, the flowing from the wart stopped. After about six more months, thanks to Dr. Budwig's therapy, I gained about 10 pounds of weight, too. The wound healed and the crust dissolved. Now there is beautiful skin. I would like to mention that I strictly adhered to Dr. Budwig's dietary rules imposed on me, linseed (flax) oil, Diäsan, "Switzerland's" cold-pressed sunflower oil; I feel very well again, I am fully able to work, the knot at the Chest has receded to a small flat hardening."

There you have it! Dr. Budwig at least with some of her patients prescribed a combination of cold-pressed sunflower oil along with the Flax oil!

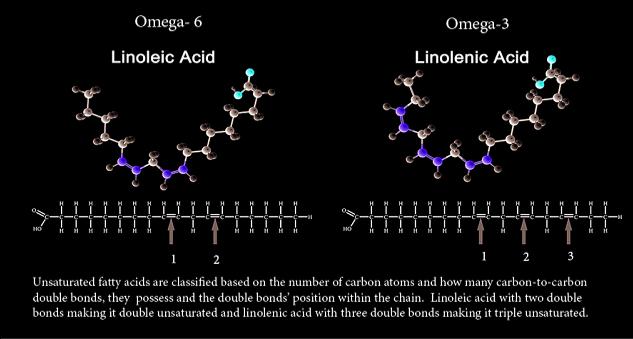

You know, I think I might have figured out why Dr. Budwig purportedly said this: "The combination of double unsaturated linoleic acid (LA) with triple unsaturated linolenic acid (ALA) is particularly well-combined in flaxseed." back in the infancy of the Fatty Acid sciences. Thus, flax oil became her apparent seed oil of choice! Lets look at the seed oils that she had listed in her patent:

Linseed (Flax) oil........................... Omega-6 Linoleic acid 16% vs Omega-3 Linolenic acid 57%

sunflower oil.................................... Omega-6 Linoleic acid 68% vs Omega-3 Linolenic acid <1%

poppy seed oil............................... Omega-6 Linoleic acid 70% vs Omega-3 Linolenic acid 0%

soya (soybean) oil........................ Omega-6 Linoleic acid 51% vs Omega-3 Linolenic acid 7%

maize (corn) oil.............................. Omega-6 Linoleic acid 59% vs Omega-3 Linolenic acid 1%

Wheat germ oil................................ Omega-6 Linoleic acid 55% vs Omega-3 Linolenic acid 7%

rice oil............................................. Omega-6 Linoleic acid 39% vs Omega-3 Linolenic acid <2%

safflower oil..................................... Omega-6 Linoleic acid 78% vs Omega-3 Linolenic acid <1%

avocado oil..................................... Omega-6 Linoleic acid 2-17% vs Omega-3 Linolenic acid 1%

You will see from the above values that Flax (linseed) oil really is the only oil that has a some what balanced amount of both Omega-6 Linoleic acid and Omega-3 Linolenic acid! All of the others tip way toward the Omega-6 Linoleic acid levels by huge margins with very little of the Omega-3 Linolenic acid present!

So, if one was to place one's self in the 1950's lab coat of Dr. Budwig and only choose one oil, then Flax oil would seem the logical balanced seed oil that contains the most Linoleic plus Linolenic acid levels of all of the others! It is a natural choice for her in a time when the ratio of both the Omega-6 and Omega-3s were not well appreciated. She knew that both were synergistic for certain, but that was about it in the knowledge banks at that time. It was not known until rather recently that linoleic acid is the prime component of cardiolipin that is found in the inner membrane of the powerhouses of our cells, the mitochondria. Linoleic fatty acid is also the major PUFA found in all of our body tissues. Had she appreciated the importance of Linoleic acid over Linolenic acid, she would probably have added on a regular basis, a high linoleic acid seed oil to her beloved flax oil to increase the Omega-6 levels in her oil/protein + quark supplement.